Novel Combustion and Emission Characteristics of Controlled Injection Atomization Using Jet-A, Carinata Bio-diesel, and Ultra Low Sulfur Diesel in an Indirect Injection Compression Ignition Engine

Location

Room 2911

Session Format

Paper Presentation

Research Area Topic:

Engineering and Material Sciences - Mechanical

Abstract

Nitrous oxides (NOx) and soot emissions are harmful byproducts in diesel engines. These emissions are a result of high temperature combustion occurring in compression ignition engines. When fuel is injected into a diesel engine, the atomized fuel spray mixes with the turbulent air in the cylinder, also called pre-mixing, before it auto-ignites. This premixing can be furthered if the spray becomes more atomized. The viscosity of the fuel is the resistance to flow of the fuel and it has a significant part in the fuel’s spray atomization property. A more viscous fuel would be more resistant to flow and would therefore have larger droplet diameters than a less viscous fuel when injected at identical injection pressures. Jet-A is a jet fuel that is used in commercial airliners in the United States however diesel engines can operate on it. Jet-A is a less viscous fuel and therefore results in a finer injection spray. Bio-diesel fuel is generally more viscous than conventional diesel fuel and would result in larger droplets during injection. A specific mixture ratio by mass of Jet-A and bio-diesel could have similar viscosity properties of diesel fuel. This study investigates combustion and emission properties of a Jet-A, a new bio-diesel called carinata, and ultra-Low Sulfur Diesel (ULSD) to discover a relationship between fuel injector spray diameters and combustion properties. These fuels will be tested in a Kubota 0.35 liter, single cylinder indirect injection engine at various loads of 1,3, and 5 bar of indicated mean effective pressure (IMEP) at 2400 RPM. Two pressure sensors in the main and pre chamber will provide combustion pressures in order to model various combustion properties for each chamber. A Mie-Diameter Spray Analyzer will be used to find injection spray diameters of each fuel and a blend of Jet-A and carinata bio-diesel that has similar viscosity of ULSD. These comparable droplet sizes will also be confirmed with a Brookfield viscometer. Combustion properties that will be investigated are ignition delay, mass burned rates, in-cylinder pressure, in-cylinder temperature, and apparent heat release rates.

Presentation Type and Release Option

Presentation (Open Access)

Start Date

4-16-2016 1:30 PM

End Date

4-16-2016 2:30 PM

Recommended Citation

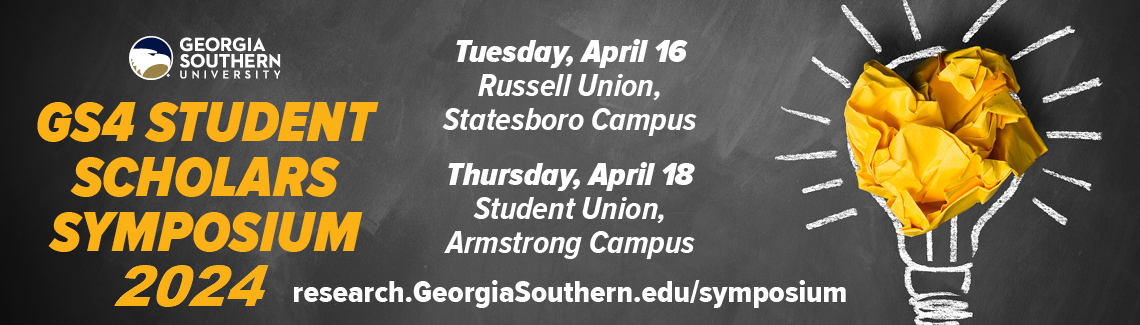

Naes, Tyler, "Novel Combustion and Emission Characteristics of Controlled Injection Atomization Using Jet-A, Carinata Bio-diesel, and Ultra Low Sulfur Diesel in an Indirect Injection Compression Ignition Engine" (2016). GS4 Georgia Southern Student Scholars Symposium. 165.

https://digitalcommons.georgiasouthern.edu/research_symposium/2016/2016/165

Novel Combustion and Emission Characteristics of Controlled Injection Atomization Using Jet-A, Carinata Bio-diesel, and Ultra Low Sulfur Diesel in an Indirect Injection Compression Ignition Engine

Room 2911

Nitrous oxides (NOx) and soot emissions are harmful byproducts in diesel engines. These emissions are a result of high temperature combustion occurring in compression ignition engines. When fuel is injected into a diesel engine, the atomized fuel spray mixes with the turbulent air in the cylinder, also called pre-mixing, before it auto-ignites. This premixing can be furthered if the spray becomes more atomized. The viscosity of the fuel is the resistance to flow of the fuel and it has a significant part in the fuel’s spray atomization property. A more viscous fuel would be more resistant to flow and would therefore have larger droplet diameters than a less viscous fuel when injected at identical injection pressures. Jet-A is a jet fuel that is used in commercial airliners in the United States however diesel engines can operate on it. Jet-A is a less viscous fuel and therefore results in a finer injection spray. Bio-diesel fuel is generally more viscous than conventional diesel fuel and would result in larger droplets during injection. A specific mixture ratio by mass of Jet-A and bio-diesel could have similar viscosity properties of diesel fuel. This study investigates combustion and emission properties of a Jet-A, a new bio-diesel called carinata, and ultra-Low Sulfur Diesel (ULSD) to discover a relationship between fuel injector spray diameters and combustion properties. These fuels will be tested in a Kubota 0.35 liter, single cylinder indirect injection engine at various loads of 1,3, and 5 bar of indicated mean effective pressure (IMEP) at 2400 RPM. Two pressure sensors in the main and pre chamber will provide combustion pressures in order to model various combustion properties for each chamber. A Mie-Diameter Spray Analyzer will be used to find injection spray diameters of each fuel and a blend of Jet-A and carinata bio-diesel that has similar viscosity of ULSD. These comparable droplet sizes will also be confirmed with a Brookfield viscometer. Combustion properties that will be investigated are ignition delay, mass burned rates, in-cylinder pressure, in-cylinder temperature, and apparent heat release rates.